Last month the Diamond Fiberglass blog post described the most common cure testing device for FRP (Fiberglass Reinforced Plastic) equipment, the Barcol Hardness Tester. This month’s blog post will describe proper use of the Barcol hardness tester to get accurate and usable data.

To maximize performance and service life of FRP equipment such as tanks or piping, the resin must achieve proper cure. Cure is expressed in hardness. Resin manufacturers publish hardness specifications; if the hardness of a certain FRP equipment is within the range provided by the resin manufacturer, it is said to have achieved proper cure and maximum performance, and service life can be expected.

The most used Barcol hardness tester is Model #934 from the Barcol-Coleman company. Before a Barcol tester is used on FRP, it should be checked for proper readings. The tester should be used on a known hardness material to confirm accuracy. Most testers are supplied with coupons of various hardnesses; the tester should indicate the correct hardness of the known hardness coupons. If it doesn’t then the tester cannot be used to measure hardness. Some Barcol hardness testers can be adjusted by the user to correct readings, but also there are Barcol certifier services that will calibrate testers to read hardness correctly. It may be obvious, but to maintain their accuracy, Barcol testers should not be mishandled or abused.

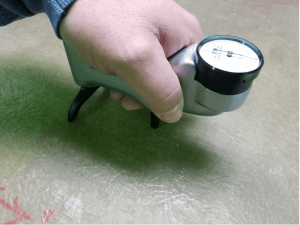

Using Barcol hardness testers properly requires cluster testing at multiple locations on the FRP item to get a clear picture of the cure of the entire part. The test surface should be clean, dry, and free of contaminants such as oil, dust, wax, etc. The FRP surface to be tested should be flat and thick enough to prevent deformation during testing. There must be reasonable access to the part surface so that the Barcol tester can be held firmly and perpendicular to the surface being tested. In addition, the FRP surface profile must have a range that does not exceed that of the tester’s probe. Most reinforcements used in FRP produce surface profiles that are within the range of most Barcol testers, so unless there are wrinkles in the fabric or other irregularities, surface profile is usually not a problem.

More accurate readings will be attained at room temperatures than in extreme hot or cold. Eventually the tip of the impressor will dirty or become dull; clean or replace as necessary.

To conduct an individual test, the Barcol hardness tester is simply pushed by hand against the FRP surface until the impressor “clicks” indicating it has probed the FRP surface properly and the measured hardness will appear on the tester’s gauge.

It is best if cluster testing can be conducted on the top, bottom and sides of the FRP equipment. If possible, test the inside, too. It is especially important to test secondary bonds, such as flanges or tabbings. Cluster test within a 3″ X 3″ (75mm x 75mm) area 10-12 times and record the readings. Each test should be in a slightly different location within the cluster test area; do not test in the exact same spot more than once.

Interested in finding out how to interpret Barcol readings in order to determine state of FRP cure? Read blog post here.

About Diamond Fiberglass Systems and Services

Diamond Fiberglass Systems and Services has been delivering value to customers since 1986. Diamond manufactures quality, custom-engineered Fiberglass Reinforced Plastic (FRP) tanks and vessels. The company also provides field services that include general maintenance, complex turnaround installations, emergency services, and on-site FRP tank inspections. Facilities are located in Texas and Louisiana. For more information about Diamond Fiberglass Systems and Services, please visit: diamondfiberglass.com, diamondservices.com, and fibrex.com.

About Andronaco

Founded in 1994, Andronaco Industries is a Total Systems Turnkey™ provider for demanding flow control and fluid management applications. Andronaco is unique in its ability to provide field services and to manufacture a broad product line consisting of multiple materials of construction. Products include lined valves, metallic and nonmetallic piping and fittings, expansion joints, hoses, system accessories, pumps, and process and storage FRP tanks and vessels. No other manufacturer in this space brings together end-to-end flow control and fluid management product needs in combination with field services for safe and reliable operations. For more information about Andronaco Industries, please visit: www.andronaco.com.

Total Systems Turnkey™ Approach

Andronaco Industries, supported by Diamond Fiberglass Systems and Services, is a Total Systems Turnkey™ provider for demanding flow control and fluid management applications. Andronaco and Diamond are unique in that we provide field services as well as manufacture a broad product line consisting of multiple materials of construction. Our products include lined metallic and nonmetallic piping and fittings, valves, expansion joints, hoses, system accessories, pumps, and vessels/tanks. No other manufacturer in this space brings together your end to-end product needs in combination with field services for your safe and reliable operations. To learn more about the Total Systems Turnkey™ Approach, please visit: The Total Systems Turnkey™ Portfolio.