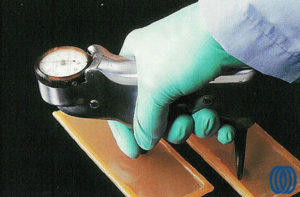

The resin in any equipment fabricated from FRP needs to attain a proper cure in order to reach its full physical properties. The most common and reliable way to determine cure stage is to use a Barcol tester. Diamond Fiberglass tests the FRP tanks and vessels it manufactures every day for proper cure. Barcol testers are easy and quick to use and are accepted in the industry as the most common way to confirm that proper cure has been attained. Manual dial and digital dial testers are available starting about $600.

A Barcol test of FRP material is a non-destructive method that measures the depth of penetration of a calibrated spring-loaded indenter into the surface of the material. The depth of the penetration is measured and compared to known depth penetrations of that particular resin when fully cured.

Resin manufacturers provide Barcol test readings for all their resins when fully cured.

The governing standard for the Barcol hardness test is ASTM D 2583. Barcol hardness is measured on a scale from 0 to 100 with the typical range being between 50B and 90B. A measurement of 60B is roughly equivalent to a Shore hardness of 80D or a Rockwell hardness M100. As defined in ASTM D 2583 the scale divisions from 0-100 should each indicate a depth of 0.0076 mm or the equivalent 0.0003 inches.

Like many other kinds of test equipment, Barcol testers should be calibrated by using a set of standard test discs with known hardness values. The Barcol tester is used on test discs and the readings compared to the known test disc hardness. The Barcol tester is then adjusted if needed achieve the correct readings.

Interested in finding out more information on the proper barcol testing procedure? Read the following blog post.

About Diamond Fiberglass Systems and Services

Diamond Fiberglass Systems and Services has been delivering value to customers since 1986. Diamond manufactures quality, custom-engineered Fiberglass Reinforced Plastic (FRP) tanks and vessels. The company also provides field services that include general maintenance, complex turnaround installations, emergency services, and on-site FRP tank inspections. Facilities are located in Texas and Louisiana. For more information about Diamond Fiberglass Systems and Services, please visit: diamondfiberglass.com, diamondservices.com, and fibrex.com.

About Andronaco

Founded in 1994, Andronaco Industries is a Total Systems Turnkey™ provider for demanding flow control and fluid management applications. Andronaco is unique in its ability to provide field services and to manufacture a broad product line consisting of multiple materials of construction. Products include lined valves, metallic and nonmetallic piping and fittings, expansion joints, hoses, system accessories, pumps, and process and storage FRP tanks and vessels. No other manufacturer in this space brings together end-to-end flow control and fluid management product needs in combination with field services for safe and reliable operations. For more information about Andronaco Industries, please visit: www.andronaco.com.

Total Systems Turnkey™ Approach

Andronaco Industries, supported by Diamond Fiberglass Systems and Services, is a Total Systems Turnkey™ provider for demanding flow control and fluid management applications. Andronaco and Diamond are unique in that we provide field services as well as manufacture a broad product line consisting of multiple materials of construction. Our products include lined metallic and nonmetallic piping and fittings, valves, expansion joints, hoses, system accessories, pumps, and vessels/tanks. No other manufacturer in this space brings together your end to-end product needs in combination with field services for your safe and reliable operations. To learn more about the Total Systems Turnkey™ Approach, please visit: The Total Systems Turnkey™ Portfolio.